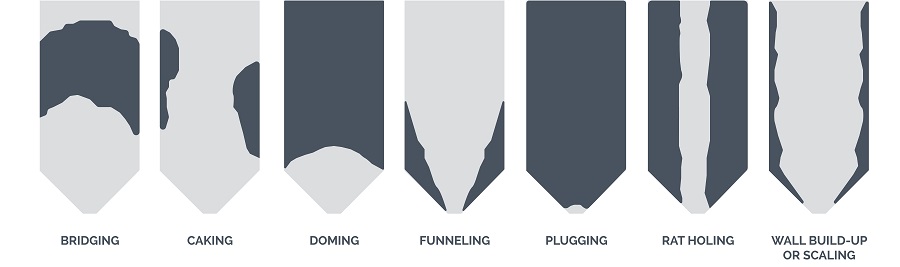

No matter the design or the materials stored, silos are susceptible to material flow issues caused by blockages. Buildup in the silo is an indication of ratholing and potentially asymmetric flow, which can increase pressure loads inside silo walls. When you have buildup in the silo, the loads associated with asymmetric flow can be detrimental to the structural integrity of the silo as they can lead to wall failure and total silo failure.

Material flow that is unimpeded by blockages is essential for smooth operations and the continued functionality of your silo. Blockages not only promote bad flow characteristics, but also lead to a reduced storage capacity.

You can help reduce the likelihood of material buildup through a number of ways. Depending on how easily stored material compacts or hydrates, your silo may need to be completely emptied on a regular schedule as often as once a month or as little as every year.

Cement Silos

To prevent stored cement from setting inside the silo, the structure must be completely watertight. Even pinhole leaks in silo roofs and walls damage your stored materials and can result in blockages and material flow issues. Ambient humidity levels can also cause some materials to set. If you do aerate stored materials, it is important to use air dryer systems to help lower the ambient humidity level in the silo. You should also avoid over aerating stored materials. Excess aeration can pump unneeded moist air into the silo which may lead to hydration of the cement.

Essential maintenance includes exterior waterproof coating(s) and keeping your air pad and air stones in good operating condition. Completely emptying your silo frequently is also important as it helps prevent compaction of stored materials.

Fly Ash Silos

It is important to keep the fly ash cool as it is loaded into the silo. Make sure your ash does not include unburnt carbon material as this can lead to material buildup along the silo walls. Chemicals from pollution control chemicals can cause your ash to become cementitious, or sticky. Coal from the Wyoming Powder River Basin is also inherently cementitious in nature. Cementitious material leads to asymmetric flow. Learn more about Fly Ash Silos.

Maintenance Schedules

It’s essential to have a proactive silo maintenance schedule, ensuring continued, safe operation.

While professional inspections are recommended every two to five years, unless there are structural or operational concerns that would necessitate more frequent inspections, frequent in-house inspections will verify that preventive maintenance measures are being followed. Silo maintenance should include regular checks of airflow units, a routine professional cleaning, and regular, complete silo emptying. Of these measures, one of the most important is the regular emptying of silos.

Silos that are regularly emptied and refilled are less likely to experience buildup issues seen in those kept topped off. Regularly emptied silos need professional cleaning less frequently in comparison. They are also less likely to experience issues like compacting and hydrating. Hydration occurs when moisture mixes with stored materials and causes them to solidify within the silo. When this happens, materials can expand and cause added wall pressure which increases the likelihood of structural failure.

The routine examination of your silo is only effective in increasing facility safety and ensuring smooth operations when it is conducted in conjunction with professional inspections (and cleaning services) as part of a regular preventive maintenance schedule. A recent case study provides an example of how asymmetric flow can cause silo failure.

To learn more, be sure to check out our full library of silo inspection videos on silo maintenance, inspection and repair on

Prevention is the most effective method to ensure the integrity of concrete structures, surfaces and silos. A proactive maintenance and inspection program is crucial to increase the life of your concrete and ensure the safety of those working around your structures. A proactive safety program should always include annual or semi-annual inspections to check for concealed damage and to assess visible problems that could lead to structural failure.

Though concrete is a superior material for the construction of storage silos, normal loading and unloading operations can lead to structural issues over time. Cracks in silo walls, linings and foundations are an indication of stress.

Concrete walls that show horizontal, vertical or diagonal cracking may be an indication of delamination, or separation of the concrete into layers. Delamination of the concrete is caused by the lack of bonding to the interior structural steel reinforcement, thus weakening the silo’s structural capacity. Issues of this nature will require repair sooner rather than later. Delamination of silo walls can lead to wall failure or collapse and should be addressed by a professional silo repair company immediately. Corrosion of metal silo components, exposed rebar or other deterioration like spalling should also be noted during a visual inspection.

Horizontal and vertical cracks are typically caused by temperature variations, moisture and internal pressure from the stored material. Cracks can cause concrete and steel rebar corrosion which can decrease wall stiffness, allow deflection, degrade durability and strength due to carbonation, and permit water penetration into the concrete wall.

To repair cracks in a poured in place silo, an epoxy injection is used to fill in the cracks. After epoxy injection, it is recommended to add post-tensioned strands completely around the silo area of delamination to provide additional structural integrity. These strands can replace all of the original steel reinforcing and, assuming the concrete is still sound, the silo can be returned to its original load capacity in an economical manner.

Much of this damage is preventable through routine inspection and maintenance. Third-party inspections, maintenance and repair services are the best way to manage safety on any scale. Many structural issues can be easily and economically addressed if caught early. One of our recent case studies inspects a slipform concrete silo with a horizontal crack.

To learn more, be sure to check out our full library of silo inspection videos on silo maintenance, inspection and repair on

Like all structures, silos degrade over time. This natural and inevitable deterioration can lead to safety hazards such as falling debris, leaks, wall failure, roof failure, and/or structural failure.

When it comes to the silo structure, the roof and its design is a crucial component. In addition to this, proper maintenance of the silo roof is a requirement but may pose a significant challenge. Many areas that may require repair are not readily visible and often structural damage is not noticed until a significant failure has occurred, the roof has settled, or the risk of impending total failure has been reached.

Leaking roofs can lead to contamination of stored materials which impact product quality. Water penetration also leads to corrosion of metal silo components like roof beams – an issue that can lead to total roof failure if not addressed. Roof beams are a frequent area of corrosion, or concrete deterioration often due to roof leaks. Spalling of concrete roof beam pockets can further expose beams and lead to eventual roof failure or collapse.

Signs of ponding water on the silo roof (as well as signs of cracking or peeling in the roof-top coating) are indicators that your roof structure is at risk. Regular ponding on the silo roof lowers the lifespan of coating membranes and can lead to deterioration and leaks. More seriously, ponding water is usually caused by issues with the supporting roof beam, potentially indicating severe underlying structural problems. Left unaddressed these problems become costlier to correct and increase liabilities.

Problems with silo roof slabs are mostly related to critical structural conditions such as material buildup, the addition of heavy equipment to the original design or flaws with the original design. The roof beam supports should have been designed to accommodate for thermal expansion and vibration from equipment and cycling of the silo by filling and discharging. This is accomplished by allowing the roof beam base plates to freely slide in the longitudinal direction over an embedded steel plate on the wall beam pocket.

The embedded plates that support the roof beams are usually involved in the failure process. Weather and temperature changes, vibration, and movement of beams cause the concrete walls to deteriorate faster around the beam pockets than the rest of the silo walls. Such deterioration leads to spalling and loosening of the bond between the embedded steel anchors and the concrete walls. When such conditions occur, the roof supporting steel beam will eventually rest on unprotected concrete. The constant thermal expansion and contraction of the beam, combined with the dead and live loads applied to it, creates a grinding force between the beam’s base plate and the silo wall. Often times this will lead to breakage of part of the silo wall immediately under the beam. When this happens, the beam shifts downward until it rests again on a solid portion of the silo wall.

Silo Repair Case Study

Beam pockets are a critical point on the silo as these roof beams hold up the roof slab and all the necessary equipment to operate the bulk storage system. One of our recent case histories examine a silo roof beam bearing repair.

Regular inspections of the underside of the silo roof along with all equipment are imperative to eliminate potential failures in any production system, including silos. Proper silo roof design is critical. While roofs are designed to hold equipment, they are not designed for excessive amounts of material. If a loading system fails or a silo is overfilled, creating bulk material on the roof, unseen damage can result and compromise the entire structure.

To learn more, be sure to check out our full library of silo construction videos on silo maintenance, repair and inspection on